Project work with C4l1brate ltd

C4l1brate Ltd has been working with engine control units (ECUs) for many years, going far beyond conventional tuning. While calibration changes remain an important part of performance optimisation, our core expertise lies in the reverse engineering, analysis, and manipulation of OEM ECU software to unlock functionality that was never originally exposed. This approach allows us to create genuine new features and operating modes within the factory ECU, rather than relying on external hardware or superficial calibration tricks.

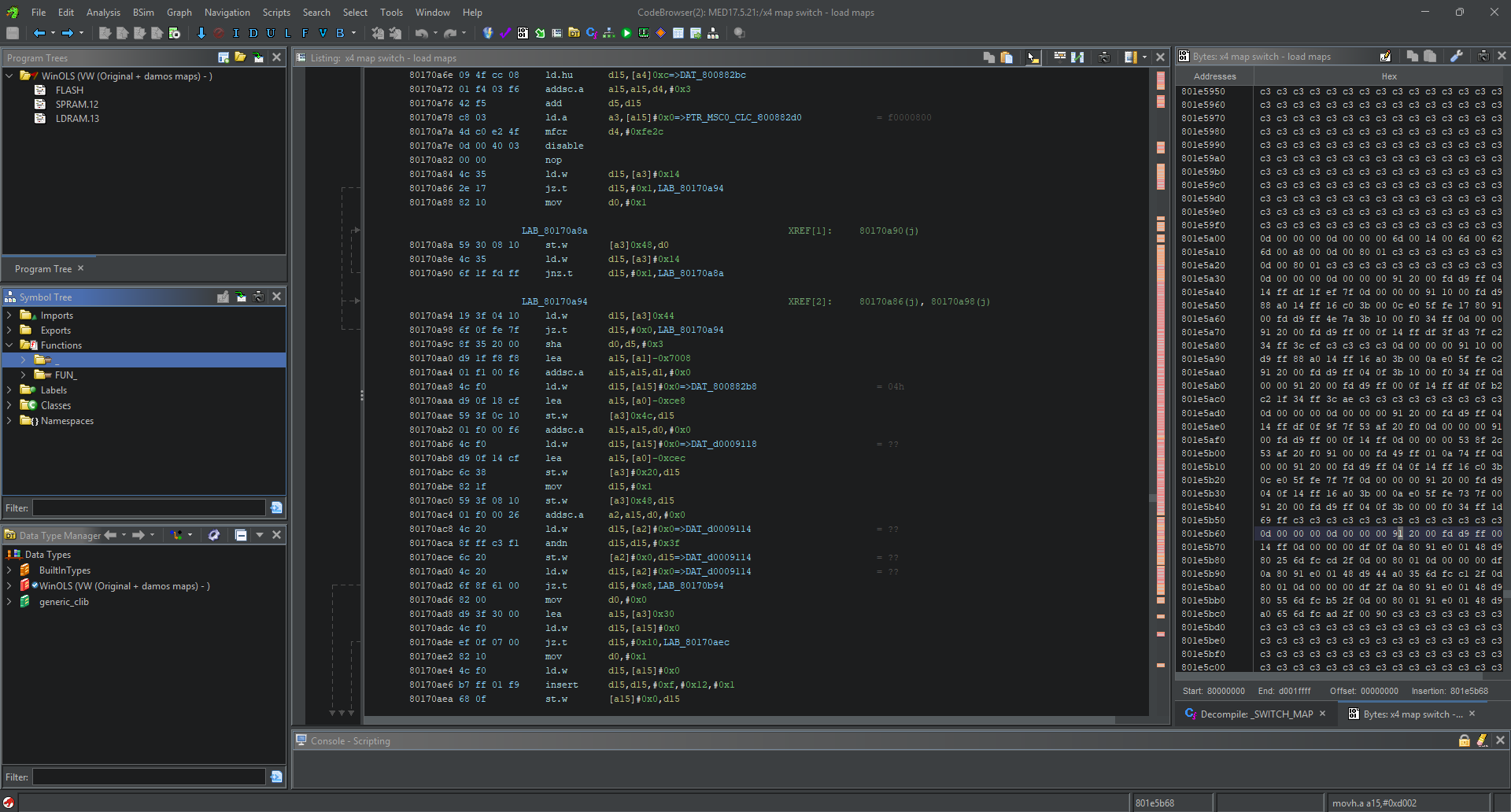

At its core, an ECU is not simply a collection of maps. It is a fully fledged embedded control system running complex software, designed to manage every aspect of engine operation in real time. The ECU program itself is divided into multiple logical areas, each with a distinct role. The

calibration area contains the data tables and maps most tuners are familiar with—fuel, ignition, boost, torque, cam control, and countless limiters.

These values define what the engine should do under a given set of conditions.

However, equally important is the

assembly (ASM) or code area, where the logic that governs how those maps are interpreted and applied is stored. This section defines the decision-making processes: how sensor data is filtered, how torque requests are calculated, how safety strategies intervene, and how different subsystems interact with one another.

Alongside this is the

RAM area, which holds live runtime data—current engine speed, calculated torque, load, temperatures, state flags, counters, and much more. This volatile memory is continuously updated while the engine is running and plays a critical role in real-time control and diagnostics.

By understanding how these areas interact, we are able to go far beyond traditional calibration. Rather than simply adjusting values within existing maps, we can modify or extend the underlying logic itself. This allows us to introduce entirely new behaviour into the ECU, effectively expanding the OEM feature set. One well-known example of this is map switching, where multiple calibrations are made available within a single ECU and selected dynamically based on defined inputs or conditions. Unlike crude implementations, properly engineered map switching requires deep knowledge of memory structures, execution flow, and safety mechanisms to ensure stability and reliability across all operating states.

This same methodology can be applied to many other advanced features: custom torque strategies, alternative boost control logic, enhanced failsafe behaviour, motorsport-oriented functions, or bespoke operating modes tailored to specific vehicle use cases. Because these changes are implemented directly within the OEM ECU, they retain factory-level integration with existing sensors, diagnostics, and communication networks, resulting in a solution that is both robust and seamless.

From a commercial perspective, this level of development is particularly valuable for businesses looking to differentiate themselves in a crowded market. While one-off custom features can be produced, they are often not cost-effective due to the time and expertise required for proper reverse engineering and validation. Where this approach truly excels is in the development of solutions that can be deployed across multiple vehicles sharing the same ECU hardware and software version. By investing in software-level innovation once, the resulting features can be scaled, reused, and monetised across an entire platform.

For tuning companies and automotive businesses, this means the ability to offer unique capabilities that competitors simply cannot replicate with standard tools. It positions your brand at the forefront of technical capability, elevates perceived value, and creates long-term competitive advantage. Instead of competing solely on price or peak power figures, you are offering engineered solutions rooted in deep ECU understanding.

If you are looking to create advanced options, proprietary features, or platform-level enhancements for your business, C4l1brate Ltd can help you achieve this. Our focus is not just on making changes, but on understanding the ECU as a system—and using that understanding to push beyond the limitations of conventional tuning.

If you would like to either have a project created for you, or just purchase an already working project, then use the contact form below, or sign upto the portal.